PLC Splitter Wafers & Chips 1xN Special Series

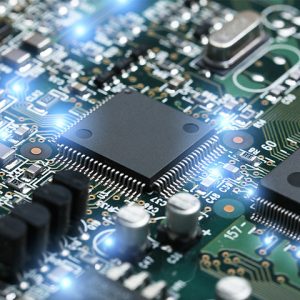

PLC Splitter is a semiconductor-based component that uses photolithography on the surface of the substrate to create waveguides to route specific percentages of light. It is a key component in the transmission system of Gigabit Passive Optical Network (GPON) and EPON networks.

PLC splitters can be found in different packages such as Bare Fiber Type, Blockless Type, Cassette Type, LGX Type and 1U Panel Type. They are highly reliable, PLC Splitter Wafers & Chips 1xN Special Series achieving high channel-to-channel uniformity and splitting ratio.

Optical Fiber Array (OFA)

PLC splitters are used in FTTH (fiber to the home) systems to split optical signals into numerous channels at different ratios. These passive devices are based on planar lightwave circuit technology and are ideal for high density applications. They feature low insertion loss, good channel-to-channel uniformity and small size. They are an integral part of any PON network and have become a standard component in most homes and businesses.

Fiber arrays are made from silica optical fibers and can be designed to operate across a wide range of spectral regions, from the near-infrared to the ultraviolet. They can be multimode or single-mode, depending on the specific requirements of a given application. Most commonly, they consist of a block of fibers with a V-groove in which optical signal channels are formed. The length of the groove, the distance between adjacent channels and the angle of the V are all customizable according to customer requirements.

Because of their complex design, constructing fiber arrays requires high precision and processing. This includes high-precision V-groove substrate processing and fiber etching technology for fabricating the desired core outlines. In addition, the end caps of the optical fibers in the fiber array must be cleaved and polished. This process can be performed using a variety of techniques, including laser-based methods that cleave the fibers in an array. After this, they are glued to the FA cover and bottom plate with soft glues, or hardened with UV-curable epoxy.

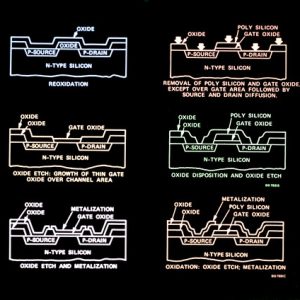

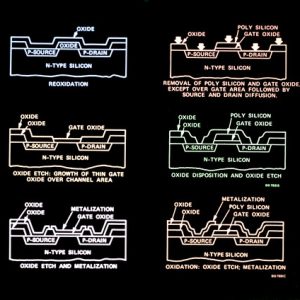

PLC Chip

PLC Chip is a programmable logic controller on a single microprocessor chip. It can be mounted in a device or machine, it needs a power supply and input/output (I/O) bus, and it must be properly grounded to avoid a static charge that could fry it. Its specialized operating system has a limited expandability, and it is designed to handle specific control tasks only.

It works like the CPU in a desktop computer, with on-board flash memory and random access memory and a few auxiliary ports. It has a serial port for communications with other chips and is available in four different types that differ in the number of on-board input and output channels.

During an input scan, the PLC reads the state of its input devices—for example, whether a switch is on or off or what value is returned by a sensor. It then compares this information to a program stored in its memory—for example, a ladder logic or function block programming language—and then determines what output devices should be activated.

Some special processes require uninterrupted operation and cannot afford to suffer even short periods of downtime. To prevent the total or partial shutdown of the process in the event of a hardware failure, redundant processor or I/O modules manufacturing fiber optic passive components with identical functionality can be added to the hardware configuration.

Fiber Array (FA) Cover Plate

The Fiber Array (FA) is a passive component of PLC splitter. The FA is used to reduce connection losses by separating transmitting and receiving signals. It consists of a V-groove substrate and a cover plate. A number of V-grooves are etched into the substrate and optical fibres are inserted into these. The V-groove is precision machined to ensure accurate fibre positioning and to minimize connection losses.

Generally, the FA is made of quartz or borosilicate glass and can be coated with an antireflection layer as required by customer. A sanded or polished surface is used to allow the insertion of the optical fiber. The whole surface is then sealed with an adhesive.

It is important to note that the FA must be mounted in such a way that the light axis of the emitting and receiving optical fibers is parallel to the cover plate. This is especially important if the FA is used in an environment with vibrations or shocks.

It is also important to pay attention to the core spacing of the optical fibres. The optimum spacing is 1 m for the single-mode optical fibres, or 2.5 m for the multi-mode ones. If the core spacing is too small, the optical device will be damaged. In addition, the alignment between the optical fibers and the matrix must be good, as this is critical for achieving a high volume-fraction of the FA.