MPO Patch Cords

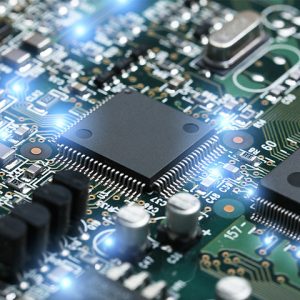

As bandwidth demands increase, MPO fiber optic patch cords offer a simple, easy-to-manage solution. But with three different polarity methods and 12 fibers per connector, MPO cables can present unique challenges when it comes to polarity management.

MPO cassettes are modular modules that house 8, 12, or 24 fiber factory terminated fan-outs in a single enclosure. They latch onto MPO adapters on the front and back to create high-density connectivity for data centers and telecommunication rooms.

Product Description

MPO (Multi-Fiber Push-on) connectors are a standard multi-core fiber optic cable interface. They are based on a clip-clamp design that is similar to LC connectors but with much higher transmission rates and greater core counts. MPO connectors are used in high-density cabling applications such as data centers and telecommunication rooms. They provide a simple and easy-to-manage solution for high-speed network connections.

MPO-to-MPO patch cords are used to connect MPO optic transceivers in telecommunication rooms or data centers. They can be either single-mode or multimode, depending on the application. The MPO-to-MPO cables are typically 12 or 24 core, supporting up to 144 or 288 fibers in total. Moreover, they are available in various lengths and colors to meet the specific requirements of your network.

These pre-terminated MPO fiber jumpers are equipped with MPO-to-MPO male and female connectors. The MPO connector is one of the MT series connectors that use two guide holes with a diameter of 0.7mm on the left and right sides of the ferrule end face. The connectors are precisely aligned via PIN pins and locked together when docking. When the MPO connectors are correctly connected, you will hear a “click” sound when the connectors are properly seated in the adapters.

The MPO-to-MPO trunk cable consists of a high-density 62.5 micron OM1 multimode optical fiber with a 3.0mm diameter. The OM1 multimode optical fiber has a configuration of mpo-patchcord 62.5 m, which is used for high-speed cabling networks. The cable is sleeved with a nonconductive riser OFNR jacket.

Product Specifications

MPO Patch Cords feature high fiber densities in a compact connector. With 12 or more fibers consolidated into a small form factor connector, these cables are ideal for high bandwidth applications and data center environments where space is at a premium.

The MPO connector is a multi-fiber ribbon connection standard that has very high mechanical and optical specs. While MPO and MTP are two different types of connectors, they look identical and intermate easily with each other.

MPO connectors have pins that line up with one another in a circular pattern around a rectangular ferrule. This allows them to mate in the same way as traditional LC and SC connectors except they require a male MPO connector to connect with a female MPO connector.

Using MPO trunk and cassettes reduces cable clutter and saves valuable floor space in data centers and other high density network environments. MPO cassettes also allow for easy upgrades and reconfigurations as technology refresh cycles occur.

This 5 meter (approximately 15ft) multimode OM3 MPO to MPO patch cord is terminated with two male MPO connectors and one female MPO connector. It uses 50 micron OM3 Corning optical fiber with an OFNP plenum jacket. It has a Method A straight through configuration for a cassette to cassette connection and supports laser optimized multimode fiber LOMMF and 10G and 40G cabling networks. It complies with TIA 568 standards for MPO connector and cable polarity methods A, B, and C.

Product Applications

MPO patch cords are used to connect ports on telecommunication equipment, such as switches and routers, to allow them to transmit data. They are commonly used in data centers, as they provide a cost-effective and reliable way to transfer large amounts of data over long distances. Compared to traditional optical cables, MPO patch cords are more compact and offer a higher fiber count in a single connector, making them a better choice for high-density applications.

MTP / MPO patch cords are available in both multimode and single-mode versions. They can be terminated directly on equipment or added to permanent structured cabling links. They are typically supplied with female MPO connectors and a type B polarity to match male MPO port configurations on transmission equipment, ensuring proper mating both from a gender perspective and a transmit/receive functionality standpoint. Other configurations are also available to match legacy backbone cabling, which requires male MPO connectors and a type A polarity.

MPO patch cords use a MPO/MTP connector, which is a high-density multi-fiber push-on style contact connection that can support up to 12 or 24 optical fibers in a single connector, greatly saving cabinet wiring space. These connectors can be connected to either MPO trunk cable or a standard CAT5e or CAT6 patch cord, depending on your infrastructure requirements. When combined with MPO or MTP adapter panels, MPO / MTP patch cords can be used to create a high-density network that provides fast and reliable connectivity for today’s high-speed networking applications.

Product Pricing

MPO patch cords are multi-fiber cables that have MPO (Multi-Fiber Push-On) connectors on both ends. These cables Internet of things are commonly used in data centers and other high-bandwidth networks. MPO stands for Multi-Fiber Push-On and is a type of clip clamping multi-core optical fiber connector. MTP (Multi-Fiber Transfer Protocol) is an advanced version of MPO, with better mechanical and optical performance. Both MPO and MTP connectors look alike, and are completely intermate able.

Cablesys offers a variety of lengths and configurations of MPO to MPO patch cords. This particular data center grade MPO fiber optic jumper cable is constructed with Corning ClearCurve ultra-bendable 50 micron OM2 multimode optical fiber glass and features MPO female connectors on both ends.

MPO fiber optic pre-connectorized cables save time and money by avoiding the need for on site splicing and termination. They use MPO fiber connectors and ribbon multi-fiber cables, which integrate multiple fiber connections into a single jacket. They support up to 72 cores, which are suitable for current 40G and 100G cabling applications as well as future network speed upgrades.