Introduction to DTF UV Film

Custom printing has taken a remarkable turn with the introduction of DTF UV film. This innovative technology is not just reshaping how we think about prints; it’s revolutionizing the entire industry. Imagine vibrant colors, intricate designs, and unmatched durability all in one package. If you’re curious about what sets DTF UV film apart from traditional methods and why it’s becoming the go-to choice for businesses worldwide, you’re in the right place. Let’s dive into this game-changing solution that promises to elevate your custom printing experience like never before!

How does DTF UV Film work?

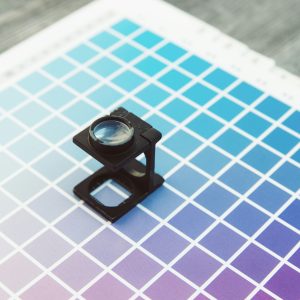

DTF UV Film operates on a straightforward yet innovative principle. It uses advanced technology to transfer high-quality images onto various surfaces. The process starts with printing the desired graphic onto a specially coated film using UV inks.

Once printed, the film undergoes curing under ultraviolet light. This step is crucial as it solidifies the ink, ensuring vibrant colors and sharp details.

After curing, an adhesive layer is applied to enhance adhesion when transferring to materials like fabric or plastic. The next phase involves heat pressing the DTF UV Film onto the chosen substrate.

The combination of heat and pressure activates the dtf uv film adhesive, bonding the design securely in place. This method allows for intricate designs that are both durable and resistant to wear over time, making it perfect for custom applications across different industries.

Benefits of using DTF UV Film for custom printing

DTF UV film offers a myriad of advantages that elevate custom printing to new heights. One standout benefit is its exceptional color vibrancy. The film captures rich, true-to-life colors that make designs pop.

Another major advantage is the quick curing process. This allows for faster turnaround times, which can be crucial for businesses needing rapid production.

The adhesion properties of DTF UV film are noteworthy too. It bonds seamlessly with various substrates, from textiles to hard surfaces, expanding creativity in design choices.

Its resistance to wear and tear also sets it apart. Prints remain intact despite exposure to harsh conditions or frequent handling.

Moreover, DTF UV film supports eco-friendly ink options. This aligns well with sustainability goals many companies aim for today.

Such benefits combine affordability and high-quality results, making DTF UV film an attractive choice for custom print projects.

Versatility and Durability of DTF UV Film

DTF UV film stands out for its remarkable versatility. This innovative material can adhere to a wide range of substrates, including textiles, plastics, wood, and metal. Whether you’re customizing apparel or creating unique promotional items, DTF UV film seamlessly adapts to your needs.

Durability is another key feature that sets it apart. Once printed and cured, designs become resistant to scratches, fading, and peeling. This resilience ensures that products maintain their vibrant colors even after repeated washes or exposure to harsh conditions.

Additionally, the flexibility of DTF UV film allows for intricate designs with fine details. From vivid graphics to delicate text elements, everything stays sharp and clear over time.

With such attributes combined into one product, businesses can confidently offer durable custom prints without compromising on creativity or quality. The possibilities are endless when utilizing this game-changing technology in various applications.

Cost-effectiveness compared to other printing methods

When evaluating printing methods, cost-effectiveness is crucial for businesses. DTF UV film emerges as a strong contender in this regard. Its ability to produce high-quality prints without the need for extensive setup reduces initial costs significantly.

Unlike traditional screen printing, which requires multiple screens and significant labor, DTF UV film allows for quick adjustments. This flexibility means you can cater to small orders or customized designs without breaking the bank.

Additionally, the longevity of prints made with DTF UV film minimizes repeat expenses. Businesses save on materials since fewer reprints are needed due to wear and tear.

Many companies have reported lower overall production costs while maintaining quality standards. As demand fluctuates, having an efficient solution like DTF UV film can lead to substantial savings over time.

Case studies and success stories of businesses using DTF UV Film

Businesses across various industries have embraced DTF UV film, transforming their custom printing processes. For instance, a local apparel brand reported a significant increase in sales after switching to this technology. The vibrant and durable prints captured customers’ attention and enhanced product visibility.

Another success story comes from a promotional products company that found new opportunities by utilizing DTF UV film for intricate designs on hard surfaces like metal and wood. Their unique offerings set them apart from competitors, expanding their customer base.

Even small businesses are reaping the benefits. A boutique gift shop began using DTF UV film for personalized items, leading to an upswing in foot traffic and online orders. Customers loved the quality and customization options available.

These examples highlight how adopting DTF UV film can revolutionize operations while delivering exceptional results that resonate with consumers.

Conclusion: The future of custom printing with DTF UV Film

The landscape of custom printing is evolving rapidly, and DTF UV film is at the forefront of this transformation. As businesses seek innovative solutions to meet customer demands, DTF UV film offers unparalleled flexibility and quality. Its ability to adhere dtf uv film supplier seamlessly to various surfaces opens up new avenues for creativity in design.

Moreover, with its impressive durability and cost-effectiveness, companies can produce high-quality products without compromising their budgets. This technology not only enhances efficiency but also simplifies the overall process from design to production.

As more businesses adopt DTF UV film into their workflows, we can expect a surge in unique applications across different industries. The future looks bright for those willing to embrace this game-changing method in custom printing. By staying ahead of trends like these, companies position themselves as leaders in innovation while delivering exceptional value to customers.