Introduction to DTG Printing

DTG printing, or direct-to-garment printing, has revolutionized the way we create custom apparel. Whether you’re a seasoned professional or just starting your journey in the world of print-on-demand, understanding the essential supplies for DTG printing is crucial to achieving stunning results. Imagine being able to bring your artistic visions to life with vibrant colors and intricate designs directly on fabric. But what does it take to turn that vision into reality? Let’s dive into the essentials that will elevate your DTG game and ensure every piece you produce looks nothing short of professional.

Benefits of DTG Printing

DTG printing, or direct-to-garment printing, offers remarkable advantages for both small businesses and large-scale operations. One of its standout features is the ability to produce vibrant and intricate designs without compromising on quality.

The process allows for full-color prints, making it easy to translate complex graphics onto fabric. This means you can experiment with creative ideas that stand out in a crowded market.

Another significant benefit is minimal setup time. Unlike traditional screen printing methods, DTG requires less preparation, enabling quicker turnaround times. This flexibility is ideal for custom orders and on-demand production.

Additionally, DTG printing supports eco-friendly practices. Many inks are water-based and non-toxic, reducing environmental impact compared to other processes.

This technique accommodates various fabric types easily—cotton blends or even specialty materials like bamboo. Thus it opens doors to diverse product offerings that appeal to different customer preferences.

Choosing the Right Printer for Your Needs

Selecting the right DTG printer is crucial for your success. Start by evaluating your printing volume. If you’re producing a small number of items, a compact model may suffice. For larger orders, consider industrial-grade printers that can handle high output without sacrificing quality.

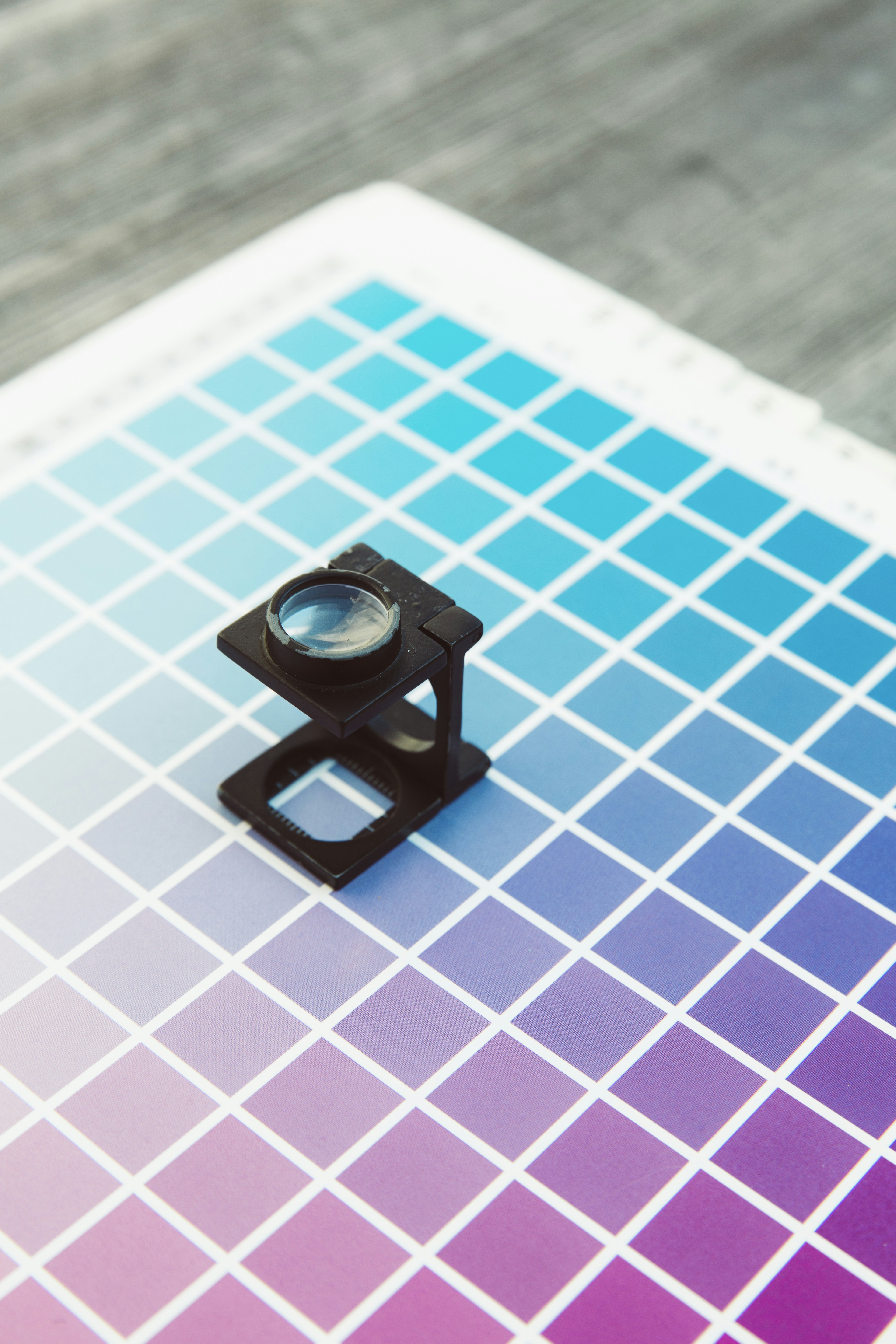

Next, think about print resolution. Higher DPI (dots per inch) means sharper images and finer details in your designs. This is especially important if you work with intricate graphics or photographs.

Don’t overlook the importance of compatibility with various fabrics. Some printers excel on cotton while others may struggle with blends or synthetic materials.

Also, factor in software support and user-friendliness. An intuitive interface saves time during setup and operation—a key advantage when meeting tight deadlines.

Consider budget constraints but avoid compromising on quality just to save costs; investing wisely pays off in the long run.

Essential DTG Printing Supplies:

When diving into the world of DTG printing, having the right supplies is crucial for success. Start with high-quality ink and a reliable pretreatment solution. These elements ensure vibrant colors and durability in your designs.

Next, consider cleaning and maintenance supplies. Regular upkeep keeps your printer running smoothly, preventing costly repairs down the line. Tools like cleaning swabs and solutions can make a significant difference.

Don’t overlook heating equipment either. A heat press or conveyor dryer is essential for curing prints effectively. This step significantly enhances the longevity of your artwork on garments.

Gather other necessary tools such as transfer papers, gloves, and measuring tapes to streamline your workflow. All these components work together to elevate your printing process from amateurish to professional-grade results.

A. Ink and Pretreatment Solution

Ink and pretreatment solution are vital components in the world of DTG printing. The right ink ensures vibrant colors and sharp details on fabric. It’s essential to choose a high-quality, water-based ink designed for direct-to-garment applications.

Pretreatment dtg printing supplies solutions prepare the fabric for printing. They create an optimal surface by enhancing ink adhesion while preventing bleeding. This step is crucial, especially when working with cotton or dark fabrics.

Different fabrics require specific types of pretreatment solutions. Understanding your material will lead to better results. Moreover, always follow manufacturer guidelines for application amounts and techniques to achieve consistent quality.

Investing in premium inks and pretreatments can significantly impact your final product’s look and feel. This attention to detail sets professional prints apart from amateur ones, making it a worthy investment for any serious DTG printer.

B. Cleaning and Maintenance Supplies

Cleaning and maintenance supplies are crucial for keeping your DTG printer in top shape. Regular upkeep not only extends the life of your equipment but also ensures consistent print quality.

Invest in a high-quality cleaning solution designed specifically for DTG printers. This will help remove any ink residue that could affect performance. Don’t forget about microfiber cloths, which are gentle on surfaces and effective at wiping down components.

Additionally, have spare parts on hand, like dampers and wipers. These can wear out over time and replacing them promptly helps avoid costly repairs down the line.

Establish a routine maintenance schedule to check for clogs or other issues. A little effort goes a long way in maintaining optimal functionality while producing stunning prints every time you hit “print.”

C. Heat Press or Conveyor Dryer

When it comes to DTG printing, the choice between a heat press and a conveyor dryer can significantly impact your workflow. A heat press is versatile and ideal for smaller operations or home-based businesses. It provides consistent pressure and temperature, ensuring that prints adhere well to fabrics.

On the other hand, a conveyor dryer excels in larger-scale productions. It allows you to cure multiple garments simultaneously while maintaining an even temperature throughout the process. This efficiency can save you time when fulfilling bulk orders.

Consider your production volume when making this decision. If you’re just starting out, a heat press might be sufficient until demand increases. However, if you’re aiming for higher output levels right away, investing in a conveyor dryer could streamline your operation significantly.

Selecting the right equipment will not only enhance quality but also improve overall productivity in your DTG printing business.

Other Equipment and Tools Needed

Beyond the primary DTG printing supplies, having the right equipment can significantly enhance your workflow. A quality computer with graphic design software is essential for creating eye-catching designs. Programs like Adobe Illustrator or CorelDRAW will help you craft stunning artwork.

You might also consider a good monitor to ensure color accuracy when designing. This helps in achieving consistent results from print to print.

Additionally, a reliable cutter or plotter can be beneficial if you’re working with vinyl or other materials alongside DTG prints. It adds versatility to your projects.

Don’t forget about storage solutions for your supplies and finished products. Proper organization prevents damage and keeps everything easily accessible.

Investing in a reliable workstation will make the entire process more efficient, allowing you to focus on creativity rather than clutter.

Tips for Properly Using and Storing Supplies

Proper usage and storage of DTG printing supplies can significantly impact your results. Always follow manufacturer guidelines for each product. This ensures optimal performance and longevity.

When it comes to ink, keep it in a cool, dark place. Temperature fluctuations can affect its viscosity and color consistency. Avoid direct sunlight, as UV rays can degrade the quality over time.

For pretreatment solutions, use airtight containers to prevent contamination or evaporation. Label them clearly with dates for easy tracking.

Cleaning supplies should be stored separately from inks and other chemicals to avoid cross-contamination. Regularly check dtg printing wholesale expiration dates on all products and replace items as needed.

Maintain an organized workspace to streamline your workflow. A tidy area reduces the chances of accidents or mix-ups with your valuable materials.

Conclusion: Achieving Professional Results with the Right Supplies

Achieving professional results in DTG printing hinges on using the right supplies. From selecting high-quality inks and pretreatment solutions to ensuring you have the necessary maintenance tools, every detail matters. A reliable heat press or conveyor dryer can elevate your final product, giving it that polished look customers desire.

Investing in quality cleaning supplies ensures your equipment remains in optimal condition. This not only prolongs the lifespan of your printer but also maintains print consistency. Storing your materials properly is just as crucial; it helps preserve their effectiveness for longer periods.

With the right combination of DTG printing supplies, you’ll be well on your way to producing stunning prints that stand out in a competitive market. Focus on what makes each component essential, and watch as your projects transform into professional masterpieces.